Ultra High Viscosity Technology

Reliably print fluids around 100 centipoises (cP) at jetting temperature

Xaar’s Ultra High Viscosity Technology allows you to reliably print fluids around 100 centipoises (cP) at jetting temperature, (approx. 1000cP at ambient temperature) which is well beyond average jetting capabilities of 10-12cP.

Ultra High Viscosity technology is available across many of Xaar’s printheads including the Xaar Nitrox, the Xaar 50x series, and Xaar 2002.

"This doesn't just open-up a toolbox, this enables an entire tool garage!"

Fluid manufacturers now have much more freedom to develop fluids which provide useful functionality.

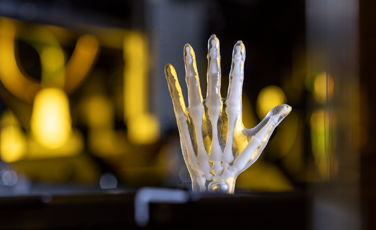

For example, Ultra High Viscosity Technology enables printing of higher molecular weight photopolymers which in turn means that printed materials can be produced with increased toughness and flexibility, useful in Advanced Manufacturing and 3D printing

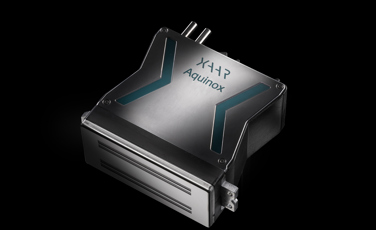

Verified by independent research

Using the Xaar Aquinox printhead and cyan water-based inks by Nazdar, The Welsh Centre for Printing and Coating, Swansea University team showed several advantages to printing high viscosity aqueous fluids, which is enabled by Xaar’s Ultra High Viscosity Technology.

- Measured colour densities were seen to be up to 60 percent higher, enabling productivity gains and an enhanced gamut by jetting the higher viscosity ink.

- High viscosity water-based fluids soaks much less into porous media (eg corrugate)

- Therefore priming becomes irrelevant, migration is reduced and less pigment is wasted through soaking into the non-coated paper

Why is this only possible with Xaar printheads?

- Xaar printheads have a unique open architecture which enables the flow of fluids freely through the printheads

- Xaar’s unrivalled TF Technology ink recirculation ensures highly reliable jetting

- The Xaar actuator (the ‘engine’ of the printhead) is extremely efficient in the way it operates

- Specialist waveforms have been developed for applications where highly viscous fluids will be printed

Industries already taking advantage of Ultra High Viscosity Technology

- 3D Printing

- Automotive

- Packaging printing

- Label printing

- Graphics printing