High Laydown Technology

Benefits of High Laydown Technology

Xaar’s High Laydown Technology enables a range of new applications, thanks to its ability to deposit large quantities of fluid in each pass.

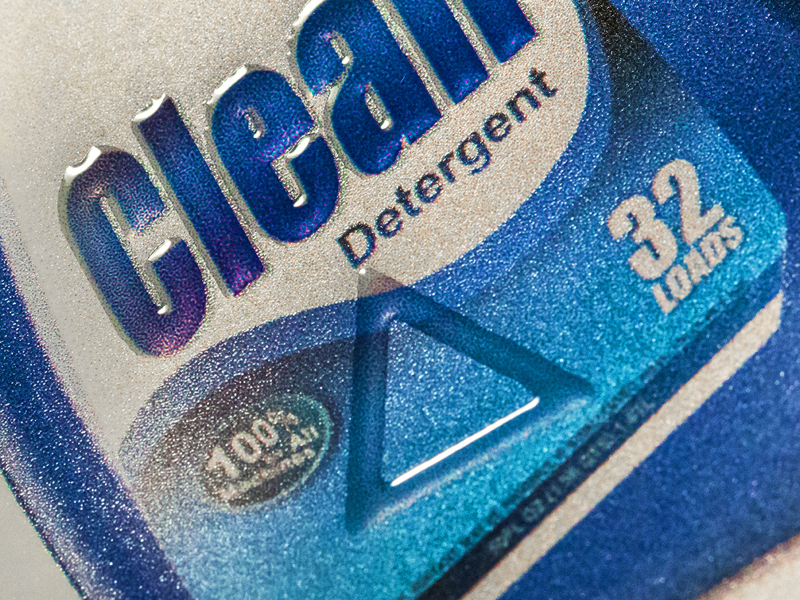

For packaging, labels and commercial print, it is capable of printing very high levels of UV inks or high build varnish in a single pass for tactile embellishments. High Laydown Technology satisfies dimension specifications for printing Braille and complies with European standards for tactile warning triangles on labels, without the complexity of screen printing.

High Laydown Technology delivers unprecedented ink discharge rates for gloss and adhesive effects on ceramic tiles, so that effects can be printed at high line speeds.

For additive manufacturing applications, High Laydown Technology offers increased printing productivity which significantly accelerates build rate for parts and the ability to print a broader range of fluids including higher viscosity materials; this ultimately results in tougher 3D printed parts than those printed with standard inkjet technology.

Printheads for High Laydown Technology

Xaar’s High Laydown Technology is compatible with Xaar Nitrox, Xaar 2002 and Xaar 1003 printheads, perfect for digitally producing tactile embellishments and dimensional effects in many applications.

What is possible with High Laydown Technology?

- Tactile embellishments on packaging and labels

- Warning triangles on labels

- Braille printing

- Gloss and adhesive effects on ceramic tiles

- 3D printing with high viscosity fluids