- Coding & marking

- Functional fluid printing

- Graphics

- Product printing

- 3D printing

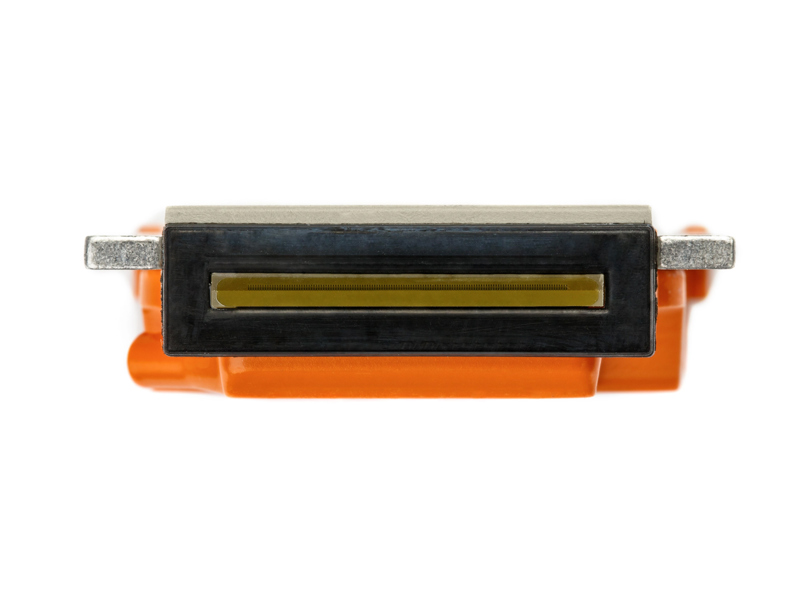

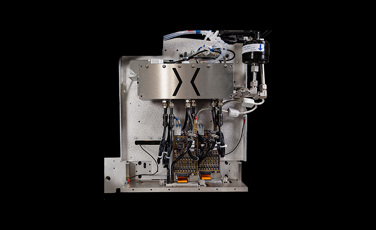

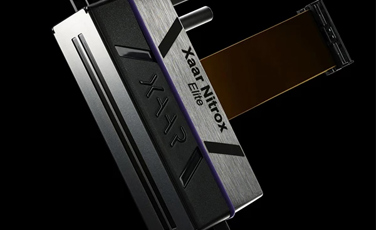

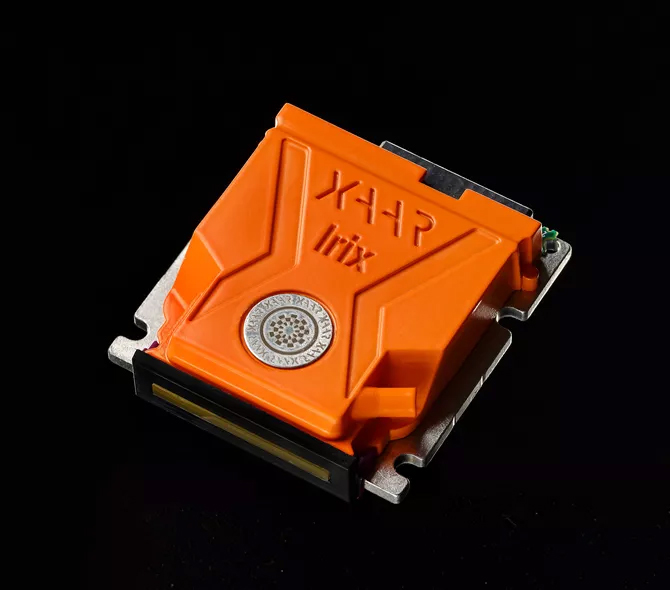

Xaar Irix

Print with confidence

+

Exceptional print quality using our latest nozzle manufacturing techniques

+

Unparalleled print uniformity with AcuDrp technology

+

Wide operating window giving increased reliability and uptime

+

Simple to use and easy to integrate

Print accurately, print reliably, print easily.

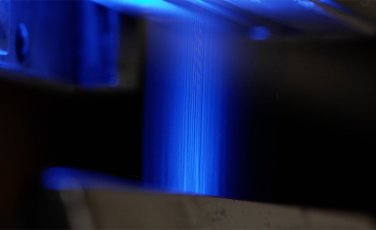

Print at greater distances

An added benefit of the improved drop placement and uniformity of the Xaar Irix is its ability to print at higher print distances.

- The Xaar Irix Core can be printed up to 5mm print distance*

- The Xaar Irix Pro can be printed up to 10mm print distance*

- Printing at low print distance can lead to media clashes which can damage the printhead

- Printing at a high print distance significantly reduces the likelihood of media clashes, keeping the printhead running for longer

- This is especially important in Coding & Marking applications where the product being printed (primary and secondary packaging) can vary greatly in size from part-to-part and across the part itself

*Ink and application dependent

Advanced nozzle technology

In-situ nozzle ablation

- Nozzle ablation is the laser process that forms the nozzles in the nozzle plate on the printhead

- The Xaar Irix utilises in-situ nozzle ablation, where the nozzle plate is attached to the printhead before the nozzles are formed

- This ensures the nozzles are perfectly aligned to the channels in the actuator, which improves angular deviation and drop placement accuracy

Individual Nozzle Ablation

- Nozzles are formed individually rather than in groups

- This ensures each nozzle has the correct geometry and produces the correct size drops at the correct velocity

Significant improvement (>60%) in drop placement accuracy

Want to find out more?

Please fill in this form and a Xaar representative will get back to you.