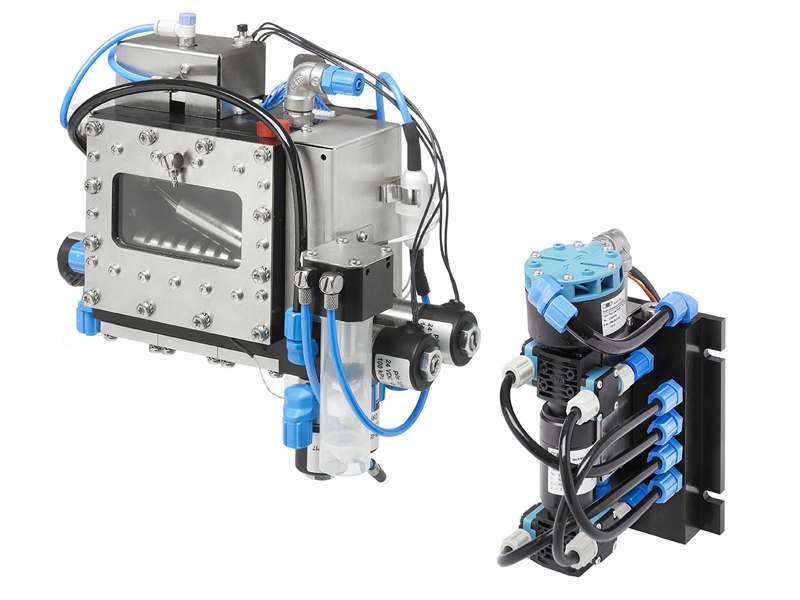

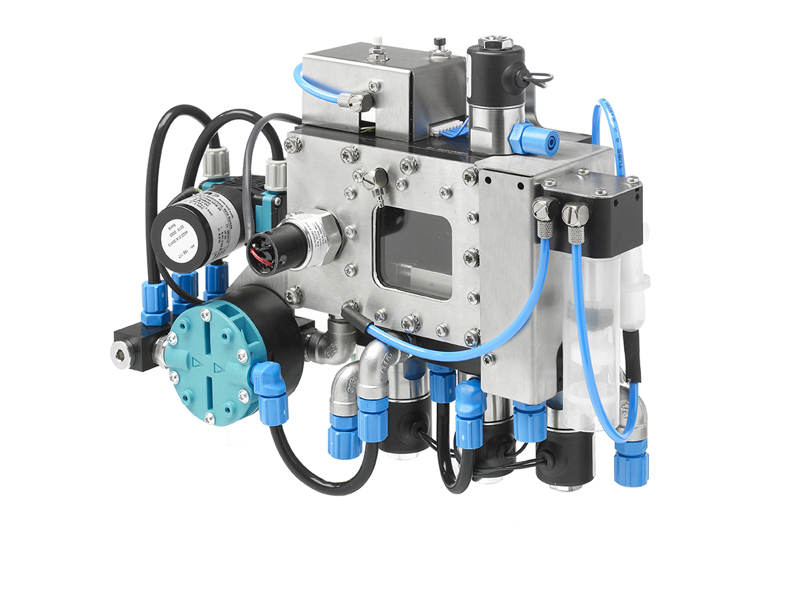

Compact system for industrial high flow and pressure-fed printheads

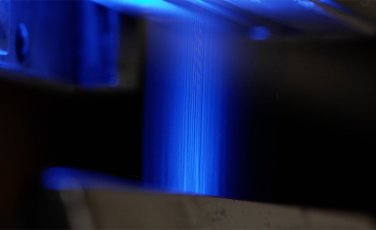

The updated Xaar Midas HV HFR Ink Supply System is a compact fluid supply system with a high volume output capable of supplying fluid for up to five individual printheads. It is ideal for OEMs and integrators who are looking to scale up to support wider printbars as well as prototype systems where a fast time-to-market and therefore low development costs are required.

Ease of integration is a key advantage of the Xaar Midas Ink Supply System. It is compact in size, easy to mount and has an ink tank capacity designed to provide a stable and reliable ink supply, ideal for integrations into larger machines.

This is a flexible solution fully compatible with all Xaar printheads and has a modular design which makes it suitable for a range of applications; it can run multiple printheads out of the box as standard and has the ability to isolate each individual output using the software for increased control and functionality.

Available in two flow rate options of either 450ml or 1500ml per minute depending on your application requirements, the Xaar Midas HV HFR 450 offers up to 450ml per minute recirculation flow rates, ideal for advanced manufacturing, direct-to-shape and other applications jetting expensive fluids. The Xaar Midas HV HFR 1500 has a fluid flow rate of up to 1500ml per minute, targeting high volume and high throughput jetting.