R&D Update jan2024

ASIC for higher resolution, higher speed Xaar printheads – significant milestone achieved

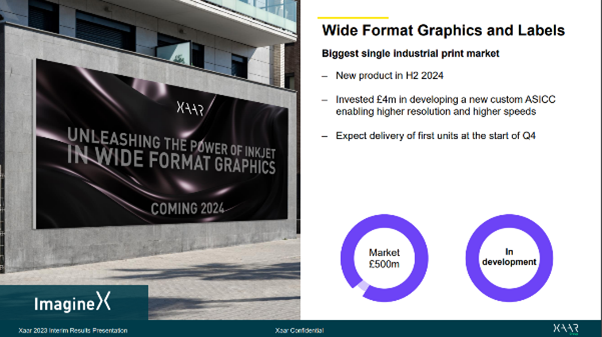

Context: “Next gen” Printhead (Enterprise) targeted at WFG and Labels – from interim Results:

The custom ASIC (Application Specific Integrated Circuit) referred to above is the “ICE ASIC” which has been developed using both internal (“ICE” project team) and External Expertise (an ASIC design house and a silicon Fab / manufacturer)

In order to do this we need a much higher connection density than the current BCLite ASIC (64 Nozzles per ASIC), and a means to reduce the heat generated on the printhead (which increases both with the number of Active Nozzles and with the print frequency)

The ICE ASIC is the means we have chosen to do this and uses a principle called Cold switching which moves much of the heat generation from the Printhead to the Drive electronics where it can be easier to deal with / remove. This is the same principle as was used for the 5601 printhead

We have with a very small project team (for a new ASIC and system development), and expertise from around the business managed to get this ASIC designed and the first engineering samples of it fabricated and assembled into a “test-vehicle” (an early prototype of a printhead)

Just before Christmas we were able to get the test vehicle with 4 ASICs on it up and running and jetting its first drops of ink (including a line onto paper) which is a significant milestone and a proof of concept. It is however just a prototype and there is still a lot of work to do before we can make a reliable, manufacturable and saleable printhead based on it.

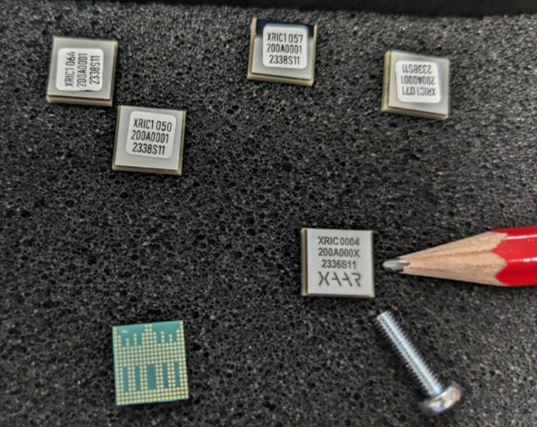

The ASIC has 132 Nozzles per ASIC in a similar foot print to the current BCL lite, and it builds on some of the technology and IP developed for the 5601 to do Cold switching specifically for Xaar’s shear mode TF Actuators

Some of the people whose expertise we have Drawn on to get this far:

Paul Brearley, Ed Taylor, Peter Boltryk, Mario Massucci, Tomas Cerny, Michael Reddish, Jurgen Brunahl

And thanks to Paul Brearley for doing the wire bonding and Phil Mead and his team for assembling the Actuator assembly together with busboard electronics into the 501 Clamshells used for the test-vehicles

And last but not least the core ICE project team:

Cezar Chirila, Steph Tweddle, Kevin Gallon, Antonio Carlini, David Capon, Nick Stapleton

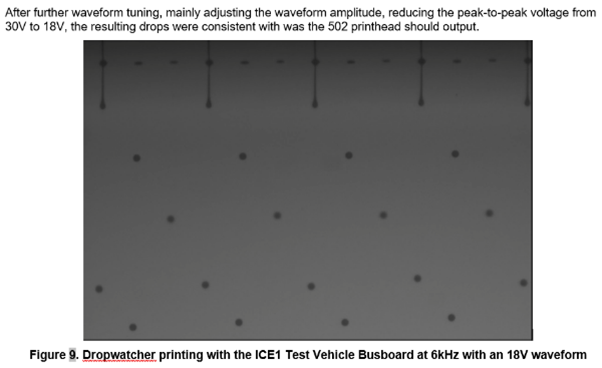

Some images below: print drops from test vehicle in Dropwatcher after some adjustment:

The ASIC (a standard pencil is shown for Size context – approx. 8.5mm square):

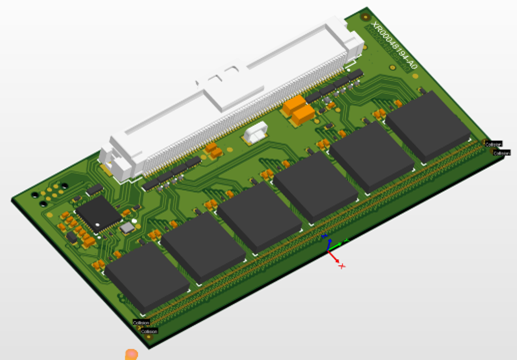

The ASICs assembled onto a busboard (501 like profile) with Flexi attached for Wire bonding:

Artists impression of a busboard with 7 of the ASICs on (similar size to a 1003 busboard but approx. 900 Nozzles per Row):